Defining Electrical Lifetimes

There remains a real interest in the delivery of systems that are partial discharge resistant - i.e. can tolerate a known level of partial discharge for a given amount of time.

It is not likely that insulation systems that can provide partial discharge resistance for the full lifetime of a product (particularly in inverter fed systems). However, insulation may only be degraded in specific portions of a flight / drive cycle as a result of specific events (e.g. high battery voltage combined with operation at high altitude, operation of the power system in an emergency condition during a fault).

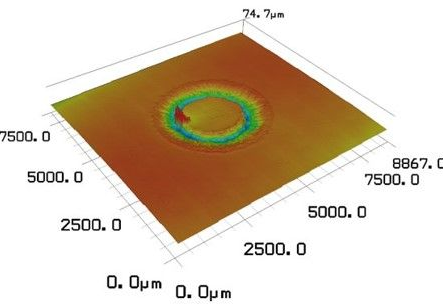

While there is significant data about the performance of insulation systems at lower frequencies (particularly 50/60Hz), there is little information about degradation at higher frequencies. Through work carried out with The University of Manchester and the Royce Institute, aHV has developed techniques that give better insight to the rate of degradation in insulation (the image on the top right showing an example of PD erosion being measured). It is hoped that we can leverage these to provide better guidance on how to assess the lifetime of an insulation system in the presence of partial discharge.

It is not likely that insulation systems that can provide partial discharge resistance for the full lifetime of a product (particularly in inverter fed systems). However, insulation may only be degraded in specific portions of a flight / drive cycle as a result of specific events (e.g. high battery voltage combined with operation at high altitude, operation of the power system in an emergency condition during a fault).

While there is significant data about the performance of insulation systems at lower frequencies (particularly 50/60Hz), there is little information about degradation at higher frequencies. Through work carried out with The University of Manchester and the Royce Institute, aHV has developed techniques that give better insight to the rate of degradation in insulation (the image on the top right showing an example of PD erosion being measured). It is hoped that we can leverage these to provide better guidance on how to assess the lifetime of an insulation system in the presence of partial discharge.

Proposed Project Scope

aHV have developed equipment that allows for multiple samples to be tested with either sinewave or squarewave at the frequencies / voltages found in future electric propulsion systems. The intention is that this equipment could be duplicated to provide increased test capability and operated on a near continuous basis over a 12 month period to produce significant volumes of data that support the development of guidelines on how to assess partial discharge resistance.

- Tests In Varying Conditions / Environments: A number of materials agreed by the project participants would be placed under test using both sinewave / squarewave voltage. The test voltages / frequencies would be varied as would the temperature / pressure of the environment within which the tests take place. The output of the tests would be threefold - the duration of the test (before failure), the erosion rate during the test (microns/hour) and the amount of material eroded before failure. Intended Outcome: Information on how the choice of voltage / frequency and environmental condition influences the failure time of materials subjected to electrical ageing. As a result of this, the development of guidance that can be used to deliver electrical endurance testing of product in a standard way - ideally enabling testing that has been carried out in one set of standard conditions to be translated to another.

- Database Of Material Performance: The testing would include the measurement of a number of common parameters (such as partial discharge inception voltage, permittivity as a function of temperature, breakdown strength) on the materials agreed by partners. This would support the establishment of a material database that could form the basis for design choices being made by engineers as they seek to develop products with a high power density. Intended Outcome: Reference material data that is relevant to inverter fed systems found in electric propulsion applications.

- Specific Test Results For Manufacturers / Users: Participants in the project will have the opportunity to nominate materials for test. If required, additional tests could be included on materials that would not be shared with the wider group (the cost of this being passed to that individual partner). Intended Outcome: Development level testing that would be targeted to improving future products of a specific partner.

Timings

Our target timings for this project are as follows:

- Agreement of project scope - May

- Finalisation of project scope and costings - June

- Project kick-off - July

Expressions Of Interest

If you would like to receive more details of this project, please contact h.jahangiri@aerospacehv.com

Contact

-

aerospaceHV Ltd

Manchester Science Park, Unit 3, Rutherford House, 40 Pencroft Way, Manchester M15 6SZ -

info@aerospacehv.com

-

+44 7410580864